Rivetless Nut Plates

ForceTec is a unique method of installing an innovative and cost effective rivetless nut plate. Unlike conventional riveted or swaged-in nut plates, the ForceTec system radially expands a retainer into a hole. The retainer is designed to be permanent, and only the nut itself requires replacement.

ForceTec rivetless nut plate system is widely used as an alternative to traditional riveted nut plates. ForceTec’s simple installation makes it a cost effective option, significantly reducing labor and maintenance costs over the life of the aircraft. ForceTec eliminates the need for satellite holes and rivets, which are required for most nut plate installations. Instead, ForceTec is fastened to the structure by radially expanding the ForceTec nut plate barrel into the hole. The expansion creates high interference between the barrel and the structure that allows the nut plate to resist torque and pushout. ForceTec installations exceed the requirements of MIL-N-25027 for torque and pushout. In addition, cold expansion of the retainers into the hole imparts compressive residual stresses into the surrounding material, increasing the fatigue performance of the hole.

Benefits of Forcetec Rivetless Nutplates

- Eliminates nut plate rivet holes

- Reduces production and manufacturing time

- Improves fatigue life of structure

- Exceeds MIL-N-25027 requirements for torque and pushout.

- Simple, quick installation.

Not sure what ForceTec product is right for your application? Give us a call or email.

The ForceTec Tooling System uses the same Puller Unit and PowerPak as our Split Sleeve Cold Expansion system, however, there are variations in the mandrels, sleeves, nose caps, and other durable tooling. A complete ForceTec system includes (but is not limited to):

- Cutting Tools

- Mandrel & Nosecap

- Split Sleeves (depending on installation method)

- Check Gages (combination & mandrel)

- Puller & PowerPak

Installation Procedure

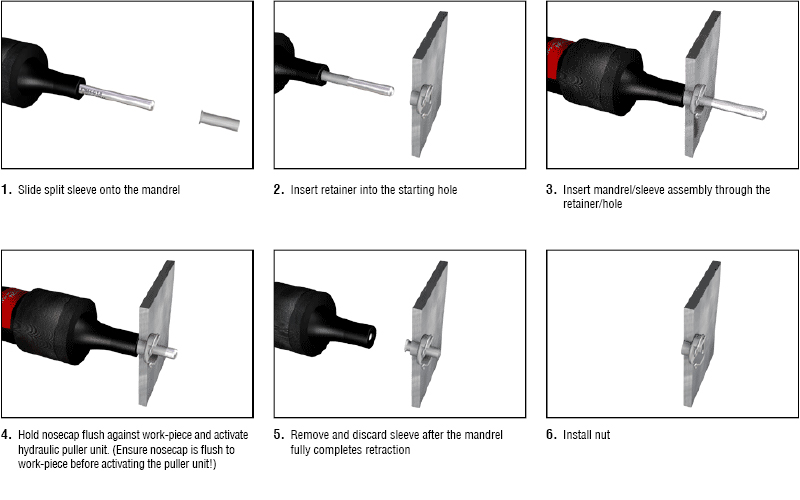

ForceTec Rivetless Nutplates can be installed using a split sleeve, mandrel only, or AIM system. The best installation for your application depends on a variety of factors including installation access, material, and desired installation speed and modularity. A major OEM time study completed of ForceTec showed that in the time it took to install 100 riveted nut plates, they could install 665 ForceTec retainers with zero defective installations. ForceTec also allows the immediate assembly of other components without waiting for adhesives to cure.

Below is an example of a classic ForceTec open retainer being installed with a split sleeve.

Product Brochures

Product Images

Product Specifications

To download any of the ForceTec Specifications listed below, please login to our Technical Library.

- ForceTec - Standard Specification 9705

- ForceTec - Aluminum Specification 2001-03

- ForceTec - Lite Specification 2008-04

FTI product systems provide simple installations, design flexibility, and improved performance. They eliminate the risk and time associated with sealants, satellite holes, and other types of interference fit products. Each product is radially expanded from an initial clearance fit to lock it into the structure and provide uniform contact with the hole surface resulting in the following advantages over other assembly methods:

- Improved open hole compression strength.

- Faster product installation and joint assembly.

- Hole protection in areas where bare holes can wear or wallow.

- Reduced arcing and laminate damage caused by lightning strike.

- Improved electrical conductivity through fastened joints to grounding locations.

- Simplified repair.

- Higher installation reliability and repeatability.

ForceTec rivetless nut plates for use in composites are available in stainless steel and titanium in a variety of sizes and configurations including open style, domed, high float, and panel fastener configurations. The nut plates are dry film lubed for a mandrel only installation using a standard FTI puller unit with a mandrel, nose cap, and chuck assembly optimized for the special characteristics of composites.

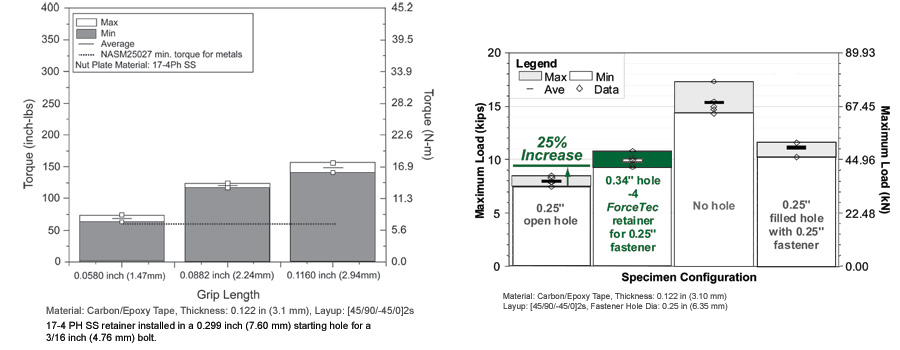

Although FTI’s installation system for ForceTec in composites uses a much lower expansion level than metals, the resulting torque out values are comparable, as the sample data below indicate. ForceTec is suitable for use in grip lengths as low as 0.06 inch (1.52 mm).

ForceTec retainers can be used to compensate for tolerance stackup in structural assembly and provide the hole filling strength advantages of a net or interference fit fastener without the access constraints or bolt removal challenges.